Nheyo yedu inotungamira ndeyekuremekedza dhizaini yekutanga yemutengi tichishandisa hunyanzvi hwedu hwekugadzira kugadzira maPCB anozadzisa zvakatemwa nemutengi. Chero shanduko kune yekutanga dhizaini inoda mvumo yakanyorwa kubva kumutengi. Pakugamuchira basa rekugadzira, mainjiniya eMI anoongorora zvine hungwaru magwaro ese uye ruzivo rwakapihwa nemutengi. Ivo zvakare vanocherekedza chero mutsauko pakati pe data remutengi uye kugona kwedu kugadzira. Izvo zvakakosha kuti unzwisise zvizere zvinangwa zvekugadzira zvemutengi uye zvinodiwa zvekugadzira, kuve nechokwadi chekuti zvese zvinodiwa zvinotsanangurwa zvakajeka uye zvinogoneka.

Kugadzirisa dhizaini yemutengi kunosanganisira matanho akasiyana-siyana sekugadzira stack, kugadzirisa saizi yekuchera, kuwedzera mitsara yemhangura, kukudza hwindo remasiki ekutengesa, kugadzirisa mavara pahwindo, uye kuita dhizaini. Idzi shanduko dzinoitwa kuti dzienderane nezvose zvinodiwa zvekugadzira uye data redhizaini remutengi.

Maitiro ekugadzira PCB (Printed Circuit Board) anogona kudimburirwa pasi kuita matanho akati wandei, rimwe nerimwe richisanganisira nzira dzakasiyana dzekugadzira. Izvo zvakakosha kuti uzive kuti maitiro anosiyana zvichienderana nechimiro chebhodhi. Matanho anotevera anotsanangura maitiro akajairwa kune akawanda-layer PCB:

1. Kucheka: Izvi zvinosanganisira kucheka mapepa kuti awedzere kushandiswa.

2. Inner Layer Production: Danho iri rinonyanya kugadzira remukati redunhu rePCB.

- Pre-kurapa: Izvi zvinosanganisira kuchenesa iyo PCB substrate pamusoro uye kubvisa chero tsvina yepasi.

- Lamination: Pano, firimu rakaoma rinonamirwa kune PCB substrate pamusoro, ichigadzirira iyo inotevera mufananidzo wekufambisa.

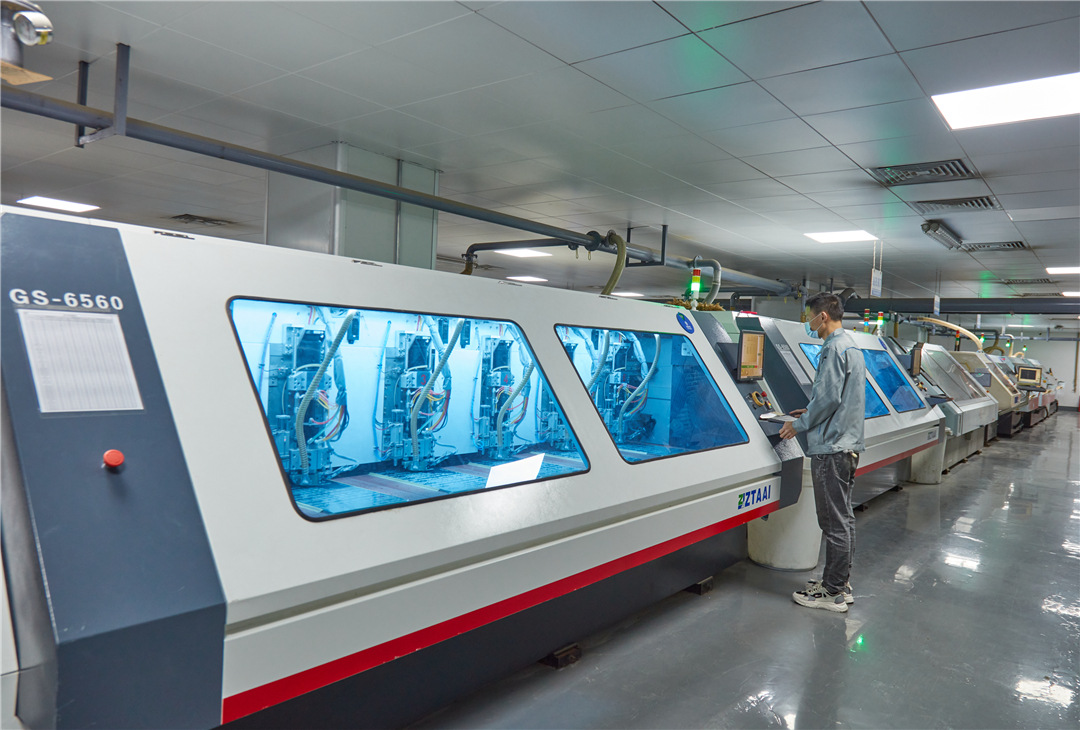

-Kuratidzwa: Iyo yakavharwa substrate inoratidzirwa kune ultraviolet mwenje uchishandisa yakasarudzika michina, iyo inoendesa iyo substrate mufananidzo kune yakaoma firimu.

- Iyo yakafumurwa substrate inozogadziridzwa, yakamiswa, uye iyo firimu inobviswa, ichipedzisa kugadzirwa kwemukati layer board.

3. Internal Inspection: Danho iri rinonyanya kuedza nekugadzirisa mapuranga ebhodhi.

-AOI optical scanning inoshandiswa kuenzanisa mufananidzo webhodhi rePCB nedata rebhodhi remhando yakanaka kuona zvakakanganiswa semaburi nemabonzo pamufananidzo webhodhi. - Chero chakakanganisika chaonekwa neAOI chinozogadziriswa nevashandi vakakodzera.

4. Lamination: Maitiro ekubatanidza akawanda emukati akaturikidzana kuita rimwe bhodhi.

- Browning: Danho iri rinowedzera chisungo pakati pebhodhi neresin uye inovandudza kunyorova kwemhangura.

- Riveting: Izvi zvinosanganisira kucheka PP kune saizi yakakodzera kusanganisa yemukati layer bhodhi nePP inoenderana.

- Kudzvanya Kupisa: Iwo akaturikidzana anodzvanywa-kupisa uye akaomeswa kuita imwechete unit.

5. Kuchera: Muchina wekuchera unoshandiswa kugadzira maburi emhando dzakasiyana-siyana uye hukuru pabhodhi maererano nezvinodiwa nevatengi. Aya maburi anofambisa inotevera plugin kugadzirisa uye kubatsira mukupisa kupisa kubva pabhodhi.

6. Primary Copper Plating: Maburi akaboorwa pabhodhi akaiswa mhangura kuti ave nechokwadi chekufambisa pazvikamu zvese zvebhodhi.

- Deburring: Danho iri rinosanganisira kubvisa maburrs pamicheto yegomba rebhodhi kudzivirira kushomeka kwemhangura.

- Glue Kubviswa: Chero glue rasara mukati megomba rinobviswa kuti riwedzere kunamatira panguva ye micro-etching.

- Hole Copper Plating: Iyi nhanho inovimbisa conductivity mukati meese mabhodhi maseru uye inowedzera pamusoro pemhangura ukobvu.

7. Outer Layer Processing: Iyi nzira yakafanana neyomukati yemukati muitiro munhanho yekutanga uye yakagadzirirwa kufambisa kunotevera kusikwa kwedunhu.

- Pre-kurapwa: Iyo bhodhi yepamusoro inocheneswa kuburikidza nekunhonga, kukuya, uye nekuomesa kuti iwedzere yakaoma firimu kunamatira.

- Lamination: Firimu rakaoma rinonamirwa kune iyo PCB substrate pamusoro mukugadzirira kunotevera kutamisa mufananidzo.

-Kuratidzwa: UV mwenje kuratidzwa kunoita kuti iyo yakaoma firimu iri pabhodhi ipinde munzvimbo ine polymerized uye isina polymerized.

-Kubudirira: Iyo isina polymerized yakaoma firimu inonyungudika, ichisiya gaka.

8. Secondary Copper Plating, Etching, AOI

-Secondary Copper Plating: Muenzaniso electroplating uye kemikari yemhangura kushandiswa kunoitwa panzvimbo dziri mumakomba asina kuvharwa nefirimu yakaoma. Iyi nhanho inosanganisirawo kuwedzera kukwidziridza conductivity uye mhangura ukobvu, inoteverwa nerata plating kuchengetedza kutendeseka kwemitsara nemakomba panguva yekucheka.

- Etching: Iyo yakadzika mhangura mune yekunze yakaoma firimu (yakanyorova firimu) yekunamatira nzvimbo inobviswa kuburikidza nekubvisa firimu, etching, uye tin kubvisa maitiro, kupedzisa rekunze redunhu.

- Outer Layer AOI: Zvakafanana nemukati me layer AOI, AOI optical scanning inoshandiswa kuona nzvimbo dzinenge dziine zvikanganiso, dzinozogadziriswa nevashandi vakakodzera.

9. Solder Mask Application: Iyi nhanho inosanganisira kuisa solder mask kuchengetedza bhodhi uye kudzivirira oxidation nezvimwe nyaya.

- Pretreatment: Bhodhi rinotora pickling uye ultrasonic washing kubvisa oxides uye kuwedzera mhangura pamusoro roughness.

- Kudhinda: Solder resist inki inoshandiswa kuvhara nzvimbo dzePCB board dzisingadi soldering, kupa dziviriro nekudzivirira.

- Pre-kubika: Iyo inonyungudutsa mune solder mask inki yakaomeswa, uye iyo inki inoomeswa mukugadzirira kuratidzwa.

-Kuratidzwa: UV mwenje unoshandiswa kurapa solder mask inki, zvichikonzera kuumbwa kweakakwira molecular polymer kuburikidza nephotosensitive polymerization.

- Kubudirira: Sodium carbonate mhinduro muinki isina polymerized inobviswa.

- Post-kubika: Iyo inki yakaomeswa zvizere.

10. Kudhindwa Kwemavara: Danho iri rinosanganisira kudhinda zvinyorwa paPCB board kuti zvive nyore kutariswa panguva dzinotevera dzekutengesa.

- Pickling: Iyo bhodhi yepamusoro inocheneswa kubvisa oxidation uye kuwedzera kunamira kweingi yekudhinda.

- Kudhinda Kwemavara: Iwo mameseji anodiwa anodhindwa kuti afambise anotevera maitirwo ewelding.

11.Surface Treatment: Iro ndiro yemhangura isina chinhu inogadziriswa pamusoro pepamusoro pezvinodiwa nevatengi (zvakadai se ENIG, HASL, Silver, Tin, Plating gold, OSP) kudzivirira ngura uye oxidation.

12.Board Profile: Bhodhi rakaumbwa maererano nezvinodiwa nemutengi, kufambisa SMT patching uye gungano.