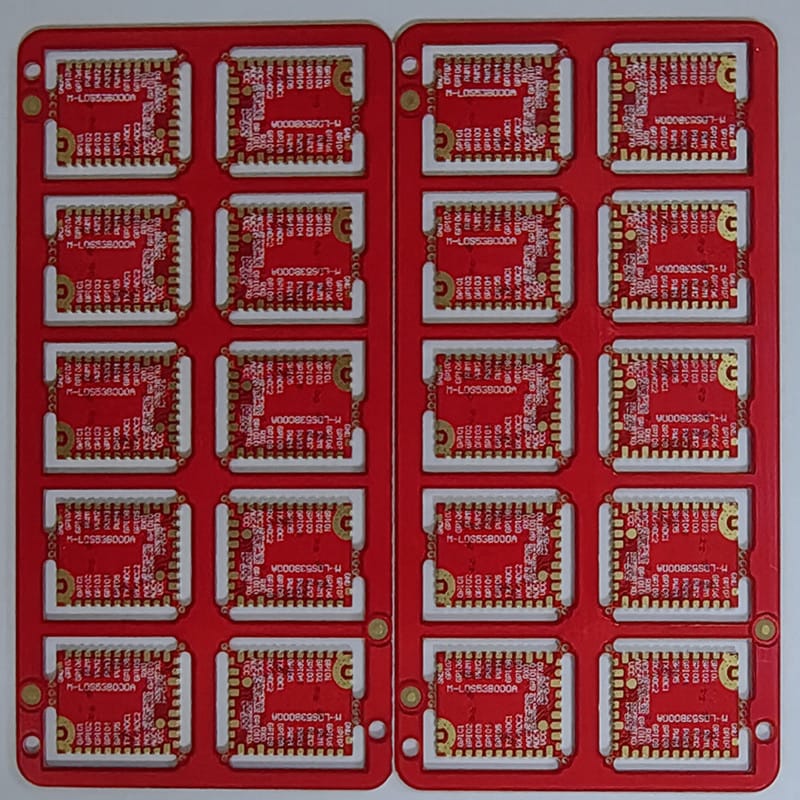

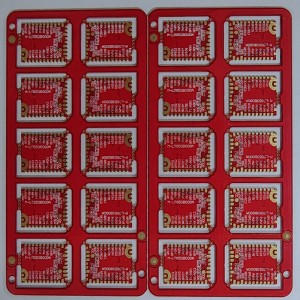

Prototype yakadhindwa redunhu mabhodhi RED solder mask castellated makomba

Mutengo weChigadzirwa:

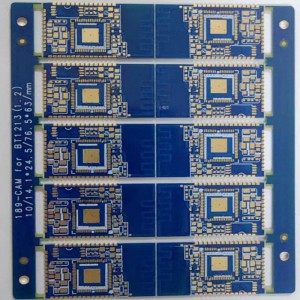

| Base Material: | FR4 TG140 |

| PCB Ukobvu: | 1.0+/-10% mm |

| Layer Count: | 4L |

| Hukobvu hwemhangura: | 1/1/1/1 oz |

| Surface treatment: | ENIG 2U” |

| Solder mask: | Kupenya kutsvuku |

| Silkscreen: | Chena |

| Special process : | Pth hafu maburi kumicheto |

Application

Maitiro ekuputirwa hafu maburi ndeaya:

1. Gadzira gomba rehafu-parutivi nekaviri V-yakaita yekucheka chishandiso.

2. Chibooreso chechipiri chinowedzera maburi padivi pegomba, chinobvisa ganda remhangura pachine nguva, chinoderedza maburrs, uye chinoshandisa groove cutters pachinzvimbo chezvibooresa kuti chiwedzere kumhanya nekudonha.

3. Nyura mhangura ku electroplate substrate, kuitira kuti chidimbu chemhangura chigadzirwe pamadziro egomba regomba rakatenderera pamucheto webhodhi.

4. Kugadzirwa kweyekunze dhizaini redunhu mushure mekucheka, kuratidzwa, uye kuvandudzwa kweiyo substrate mukutevedzana, iyo substrate inoiswa kune yechipiri mhangura plating uye tin plating, kuitira kuti mhangura yemhangura pamadziro egomba regomba pamucheto webhodhi yakakora uye mhangura yemhangura yakafukidzwa neyakafukidzwa netini rekudzivirira kupisa;

5. Kuumba hafu-gomba cheka gomba rakatenderera pamucheto wepuranga muhafu kuti uite hafu-gomba;

6. Muchinhanho chekubvisa firimu, firimu re-anti-electroplating rakatsikirirwa panguva yekufambisa firimu inobviswa;

7. Etching substrate yakavharidzirwa, uye mhangura yakazaruka pamucheto wekunze we substrate inobviswa ne etching;

8. Tini inobvisa substrate inobviswa tini, kuitira kuti tini pamadziro ehafu-gomba inogona kubviswa, uye mhangura yemhangura pamadziro ehafu-gomba inoratidzwa.

9. Mushure mekugadzira, shandisa tepi tsvuku kuti unamatire mabhodhi eyuniti pamwe chete, uye bvisa maburrs kuburikidza nealkaline etching line.

10. Mushure mechipiri chemhangura yemhangura uye tin plating pa substrate, gomba rakatenderera pamucheto webhodhi rinochekwa nehafu kuti riite hafu yegomba, nokuti mhangura yemhangura yemadziro egomba yakafukidzwa nesimbi yetini, uye mhangura yemhangura yegomba rusvingo yakanyatsopindirana nemhangura yemhangura yekunze kwekunze kweiyo substrate inogona kudzivirira kubatanidzwa kwemhangura, iyo inogona kudzivirira kubatanidzwa kwemhangura. gomba madziro kubva pakudhonzwa kana copper warping pakucheka;

11. Mushure mokunge hafu-gomba kuumbwa kwapera, firimu inobviswa uye ipapo yakamisikidzwa, kuitira kuti mhangura pamusoro hakuzovi oxidized, zvinobudirira kudzivisa kuitika kwasara mhangura kana kunyange pfupi redunhu, uye kuvandudza goho mwero we metallized hafu-gomba PCB redunhu bhodhi.

FAQs

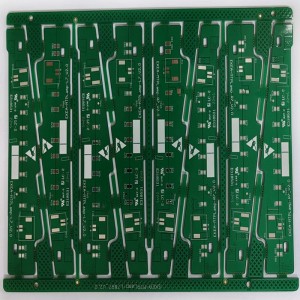

Yakaputirwa hafu-gomba kana castellated-gomba, idanho rakaita chitambi mupendero kuburikidza nekucheka nepakati pane iyo rondedzero. Yakaputirwa hafu-gomba ndeyepamusoro-soro yemapendero akapfava emapuranga edunhu akadhindwa, anowanzo shandiswa kubatanidza bhodhi-kune-bhodhi.

Via inoshandiswa seyakabatana pakati pemhangura zvidimbu paPCB nepo PTH ichiwanzoitwa yakakura kupfuura vias uye inoshandiswa segomba rakavharwa rekugamuchirwa kwechikamu chinotungamira - senge asiri SMT resistors, capacitors, uye DIP package IC. PTH inogona zvakare kushandiswa semaburi ekubatanidza mechaniki nepo vias ingasadaro.

Iyo yekuputira pamaburi imhangura, conductor, saka inobvumira conductivity yemagetsi kufamba nemubhodhi. Zvisina-plated kuburikidza nemakomba hazvina conductivity, saka kana iwe ukazvishandisa, iwe unogona chete kuva nemakwara emhangura anobatsira kune rumwe rutivi rwebhodhi.

Kune mhando nhatu dzemakomba muPCB, Yakaputirwa Neburi (PTH), Non-Plated Through Hole (NPTH) uye Via Holes, izvi hazvifanirwe kuvhiringika neSlots kana Cut-outs.

Kubva kuIPC chiyero, ndeye +/-0.08mm yepth, uye +/-0.05mm ye npth.